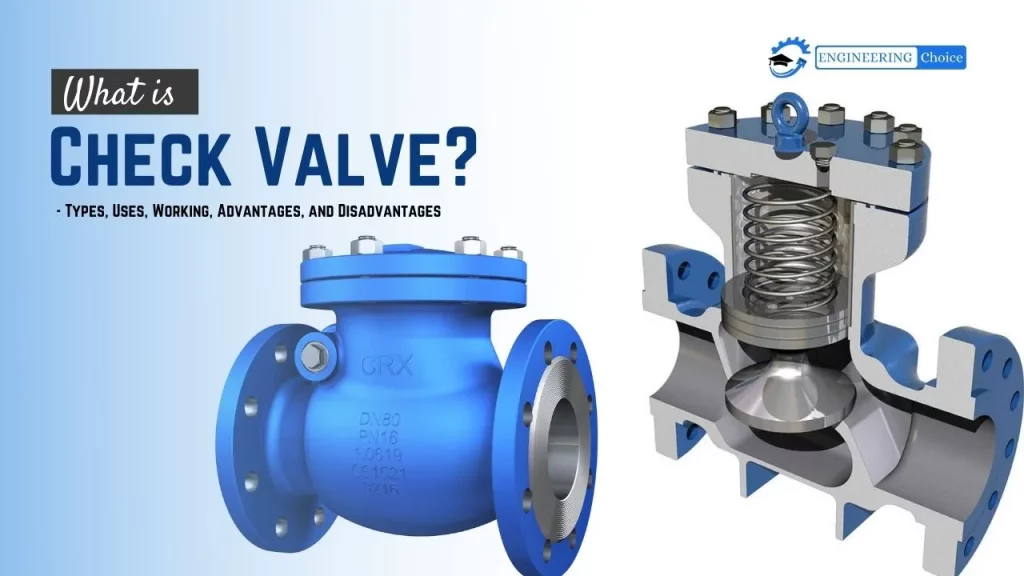

When the order is provided to open somewhat in standard valves, there is no input to confirm that the valve has opened to that position. Instead, the order is given with a valve positioner, and the valve positioner peruses the opening, confirming the position and correcting until it gets it to the specific position required. This considers incredible accuracy in the adjustment. What is Check Valves? Check valves are designed to permit the progression of liquid across a pipeline framework or port one way as it were. They are responsive valves, implying that they are initiated by the sum and the pressure of the liquid present in the framework climate. Check valves are ordinarily utilized in reverse counteraction applications, flood avoidance conditions, and wastewater treatment substances.

Notwithstanding the valve positioners, valve items themselves merit our consideration. There are many groupings. Among all of those valve types, the check valve is one of the principal sorts. It is used to close off diverting and to prevent release. Discharge happens when the substance in the line streams the other way when the valve is shut. There are many types of these kinds of valves, for example, ball check valves, stop-check valves, cone check valves, plate check valves, etc.

The top class is the most widely recognized one. A ball in the valve shell fits steadily against the side of the valve where the water comes in. Also, water pushing through the line moves the ball against the spring, allowing water through the valve. When the water is wound down, the ball is driven into place by the spring and holds water back from streaming in reverse through the line.

The next sort is an item with supersede control to stop stream paying little heed to stream heading or pressure. It cannot just close because of discharge or lack of forwarding pressure. In addition, it can be purposely closed by an outer component, along these lines forestalling any stream paying little mind to advance pressure.

The third is like ball check valves, yet the attachment that seals the valve is molded like a cone. It additionally can be known as a lift check valve in which the circle, in some cases called a lift, can be lifted off its seat by higher pressure of gulf or upstream liquid to permit stream to the power source or downstream side. The cone is hung on a bar, allowing it to lift far removed when the water is streaming and drop again into the right spot when the water is off. If water discharges through the line, it pushes facing the cone. And making a seal that holds it back from going any further.

The plate valve is generally called the swing check valve. It works correspondingly to ball and cone valves, yet the connection that settles over the opening is a plate. Circle and cone valves will, as a rule, destroy more because they have extra moving parts and because they get thumped around on top of the movement of the water when it is turned on.